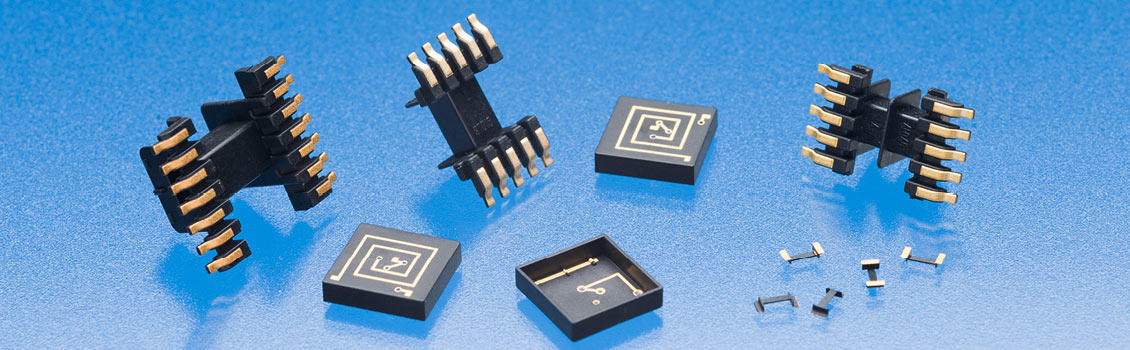

The LDS-method uses special plastic materials with additives. After a partial activation by laser conductor layers are created in a chemical reaction. NORWE has further developed this technology by using cross-linked plastic materials to allow winding on the plastic without solder-pins.

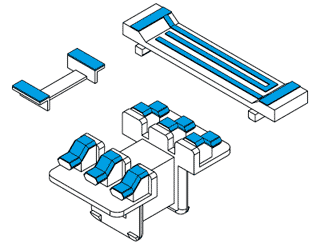

The advantages are convincing – downsized components, simplified connecting technology, lower weight, optimal coplanarity as well as the possibility to provide smaller and medium-sized series without expenses for a pinning technique.

NORWE uses this method amongst others for SMD-components of the SMD3-series and already for solutions to customers’ specifications. Our specialists will be glad to answer your questions.

The NORWE LDS-process

Step 1

The components to be laser structured are produced by injection moulding. NORWE uses a plastic material doped with additives which has specially been developed for laser structuring and cross-linking. This technology allows the use of high temperatures during the soldering process.

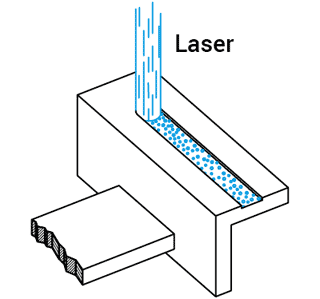

Step 2

The plastic components are activated with a laser beam. This process induces a chemical reaction at which the metal particles that track form the nuclei for the subsequent metallization. In addition to the activation the laser creates a micro-roughened surface in which the copper is firmly anchored during the metallization. There are practically no limits regarding the width or tracking of metallized surfaces – even three-dimensional designs, like for the SMD3- coilformers, are possible.

Step 3

The metallization of the components takes place in current-free copper baths. The desired thickness of the copper layer can be influenced by changing the exposure time in the baths. The copper is coated with a nickel layer. A thin gold finish is created, to ensure best solder properties.

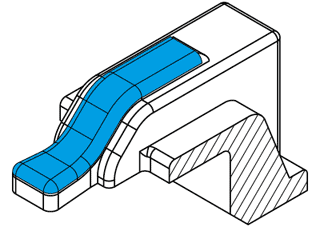

Step 4

The finished components are compatible with conventional winding and soldering processes, as due to the plastic material used they withstand short-term temperatures of 450–500°C. The gold finish ensures short solder times in the tin bath. Moreover the coilformers which are mostly SMD-components are reflow solderable without any restrictions.