EP-Series

This catalogue of coilformers contains information on all our products of the EP-Series

EP cores allow the design of transformers with high inductance, requiring only small space. The compact design also minimizes stray-fields. We supply coilformers made in high quality thermoplastics, matching your production requirements. This catalogue also contains data of clips, which may be required to secure the ferrites.

Wherever high-temperature soldering processes are used in connection with EP-series coilformers, we recommend radiation cross-linked plastics. This ensures that the mechanical properties - in particular those of gfr-polyamides - are maintained and breakages are reduced. For this reason NORWE offers all plastic components of the EP-series in irradiated cross-linked materials. Basically a cross-link enhancer is added to the thermoplast. The thermoplastic components are then exposed to Beta and/or Gamma radiation and cross-linking takes place.

Through cross-linking the material loses its thermoplastic characteristics. It is, however, not a thermoset material. In the short term, the cross-linked materials can be exposed to very high temperatures. Apart from improved aspects in production there may be interesting cost advantages.

Our extensive range of modular tooling allows almost unlimited constructional changes to meet customers specification, often by simple changes of tool inserts. In addition the modular tooling system allows extremely short tooling times and can be very cost effective.

Should you need further assistance we look forward to hearing from you.

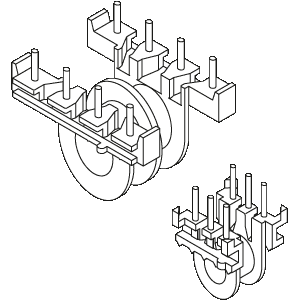

EP - Coilformers with Solder-pins

The coilformers are made in gfr Polyethylene Terephthalate PET of type rtg nat. (RTI long-range temperature +155°C). Pin material: tin bronze, tinned. Maximum solder temperature 350°C, 2 sec.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coliformers are fitted with straight pins. Binding-on of the wires is axially. The terminal strips usually feature "noses" which provide tension-relief, and "stand-offs" which allow clean soldering of the wires and of the coilformer onto the pcb.

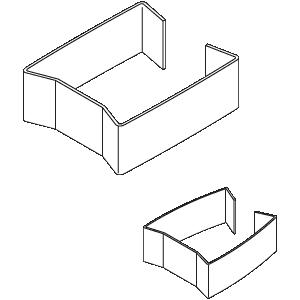

Spring-Clips SB-EP

Glueing methods are usually used to connect and secure the ferrite cores. Glues, such as Araldite, require the ferrite cores to be kept under constant pressure until the glue has hardened. A more advantageous and quicker method is by using stainless steel clips SB. The holding pressure is almost constant over the whole operating temperature range.

One clip is required to assemble a wound coilformer with one pair of ferrite cores. The use of a drop of glue is recommended, to connect the ferrites to the coilformer and to prevent frequency noise.

Dimensions in mm/inch.

When ordering please quote type and order-code.

Ordering Example

Please kindly take all details which are necessary to execute your order correctly from the ordering example (pdf-file).

Additional Product Informations

For explanatory and more detailed information on this coilformer-series please kindly see the attached pdf-file.

- Information of EP-Series

- EP Ferrite Cores

- List of Thermoplastic Materials