UNI-Series

This catalogue contains information on all our products of the UNI-Series (safety class coilformers and components)

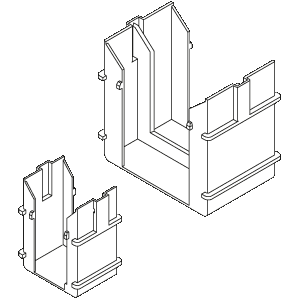

Universal coilformers (UNI) are available for lamination sizes El and EE different stack dimensions. The coilformers can be used universal in single or double section design. By fitting shrouds and insulating bridges, safety class to VDE 0551 / IEC 14 d is achieved. Coilformers are also available with pockets to fit thermal fuses or cutouts.

We supply coilformers made in high quality thermoplastics, matching your production requirements. In addition, accessories such as contact parts, temperature fuses and clips, are also covered, as is information on shrouds and insulating bridges.

Wherever high-temperature soldering processes are used in connection with UNI coilformers, we recommend irradiation cross-linked plastics. This ensures that the mechanical properties - in particular those of gfr-polyamides - are maintained and breakages are reduced. For this reason NORWE offers all plastic components of the UNI-series in irradiated cross-linked materials.

In the short term, the cross-linked materials can be exposed to very high temperatures. Apart from improved aspects in production there may be interesting cost advantages, and a discussion with us could be useful.

Should you need further assistance, be it technical or to assist when placing your order, we look forward to hearing from you.

Our extensive range of modular tooling allows almost unlimited constructional changes to meet customers specification, often by simple changes of tool inserts.

In addition this modular tooling system allows extremely short tooling times and can be very cost effective.

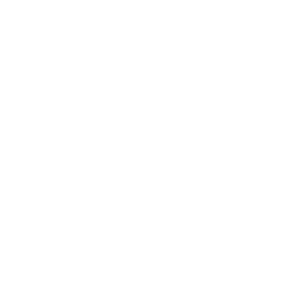

UNI EE Coilformers

The coilformers are made in gfr Polyamide PA66 of type p6g (RTI long-range temperature +125°C). Pin material is tin bronze, tinned and brass, tinned for solder-tags. Max. solder temperature 350°C, 2 sec.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coilformers are fitted with solder-pins alternatively with solder-tags for litz-wire.

Fitting the additional shroud achieves creepage- and clearance dimensions of 8 mm/0.315 inch between primary and secondary, and 4.8 mm/0.189 inch to the core.

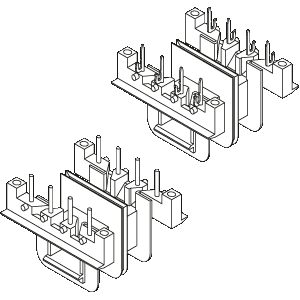

UNI EJ Coilformers

The coilformers are made in gfr Polyamide PA66 of type p6g (RTI long-range temperature +125°C). Pin material is tin bronze, tinned and brass, tinned for solder-tags. Max. solder temperature 350°C, 2 sec.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coilformers are fitted with solder-pins and solder-tags.

By fitting shrouds and insulating bridges creepage- and clearance distances of 11 mm/0.433 inch are achieved between primary and secondary, and 6 mm/0.236 inch to the core.

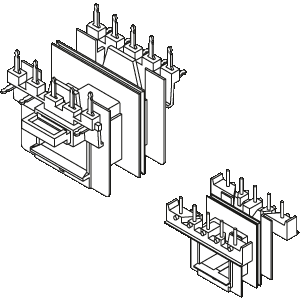

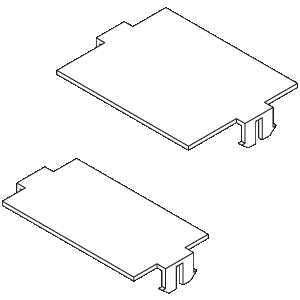

Shrouds for UNI EE Coilformers

The shrouds are made in gfr Polyamide PA66 of type p6g (RTI long-range temperature +125°C).

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The shrouds are easily fitted and latch into the coilformer, giving a cost-effective method of safety insulation.

The reinforcement ribs on the shrouds act as a guide when laminating and also secure the top and bottom sets of laminations.

When ordering please quote type and order-code.

Shrouds for UNI EJ Coilformers

The shrouds are made in gfr Polyamide PA66 of type p6g (RTI long-range temperature +125°C).

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The shrouds are easily fitted and latch into the coilformer, giving a cost-effective method of safety insulation.

The reinforcement ribs on the shrouds act as a guide when laminating and also secure the top and bottom sets of laminations. Please note that double section UNI EJ coilformers with a compartment for a thermofuse require an additional insulating bridge to achieve safety insulation.

When ordering please quote type and order-code.

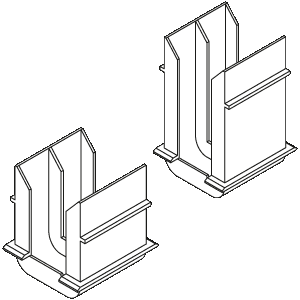

Insulating Bridges

The isulating bridges are made in gfr Polyamide PA66 of type p6g (RTI long-range temperature +125°C).

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

Double section coilformers which have a compartment for a plug-in thermofuse require a bottom insulating bridge to achieve 11 mm/0.433 inch clearence- and creepage dimensions between primary and secondary windings.

The insulating bridge latches into the main shroud and can then not be removed.

When ordering please quote type and order-code.

Ordering Example

Please kindly take all details which are necessary to execute your order correctly from the ordering example (pdf-file).

Additional Product Informations

For explanatory and more detailed information on this coilformer-series please kindly see the attached pdf-file.

- Information of UNI Safety class coilformers

- Description of the designs press-fit solder-pins or press-fit solder-tags

- Description of the designs side-wrapping solder-tags

- Survey of Solder-pins and Solder-tags

- Information of NORWE thermoclip

- Winding data tables

- Lamination

- List of Thermoplastic Materials

- Description Irradiation Cross-Linking