RM-Series

All our products of the RM-Series

The components of the RM-Series are of compact and almost closed design. They are especially suitable for pulse transformers, storage chokes, filter application or DC-converters. We supply components made in high quality thermoplastics, matching your production requirements.

Wherever high-temperature soldering processes are used, we recommend irradiation cross-linked thermoplastics. Cross-linked materials can be exposed to short, but very high peak temperatures. Beside improved production aspects there may be also interesting cost advantages.

Our extensive range of modular tooling allows constructional changes to customers specification by simple changing tool inserts. In addition the modular tooling system allows short tooling times and can be very cost effective.

Should you need further assistance we look forward to hearing from you.

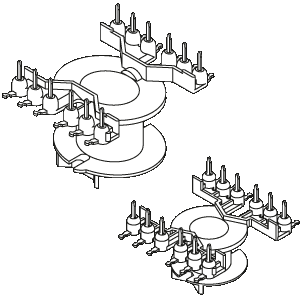

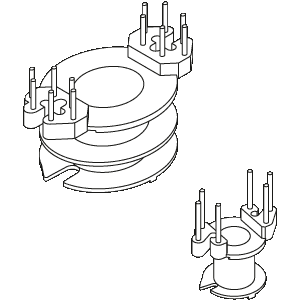

Standard RM, RM-LP Low Profile with Dual-in-Line solder-pins

The coilformers are made in gfr Polyethylene Terephthalate PET of type rtg nat. (RTI long-range temperature +155°C) and made in gfr Polyamide PA66 of type p6g (RTI long-range temperature +125°C). Pin material: tin bronze, tinned. Maximum solder temperature 350°C, 2 sec.

Special materials - eg. irradiated cross-linked - and designs on request, dimensions in mm/inch.

Two types of Dual-in-Line solder-pins can be fitted. L-shaped type h for radial binding on, side wrapping and soldering. Tension relief for thin or litz wire is possible. Straight solder-pins type z for axial binding-on and soldering. Less pcb area is required using this solder-pin.

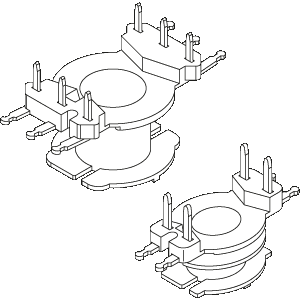

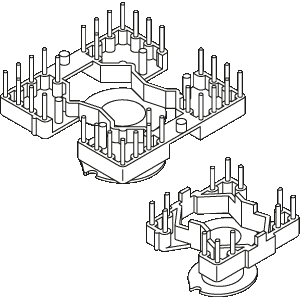

Standard RM, RM-LP Low Profile with Dual-in-Line solder-tags

The coilformers are made in gfr Polyethylene Terephthalate PET of type rtg nat. (RTI long-range temperature +155°C), Polyamide PA66 of type p6g (RTI long-range temperature +125°C) and A3X2G10 (RTI long-range temperature +115°C). Tag material: brass, tinned. Maximum solder temperature 350°C, 2 sec.

Special materials - eg. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coilformers have two rows of solder-tags, pcb-style dual-in-line. Binding-on of thin wire and litz can be done radially, and tension relief is possible.

A tolerance-compensator (TA) on the top flange eliminates the normally used spring-washer.

Standard RM 45° with Dual-in-Line solder-tags

The coilformers are made in gfr Polybutylene Terephthalate PBT of type pcg (RTI long-range temperature +130°C). Tag material: brass, tinned. Maximum solder temperature 350°C, 2 sec.

Special materials - eg. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coilformers have up to 3 solder-tags dual-in-line. Binding-on can be done radially. Tension relief for thin wire or litz is achieved by bending the tag-sides towards the winding section.

A tolerance-compensator (TA) on the top flange eliminates the normally used spring-washer.

RM Power Conversion 45°

The coilformers are made in gfr Polyphenylene Sulfide PPS of type torA504 (RTI long-range temperature +130°C).

Pin material: tin bronze, tinned. Maximum solder temperature 300°C, 2 sec.

Special materials - eg. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coilformers are fitted with straight solder-pins. Binding-on of the wires is axially. The wires are guided into the winding room through centrally positioned slots in the lower flange. A reinforced flange reduces the risk of breakage when binding-on the wire and ensures a tight fit of the solder-pins which are inserted after moulding.

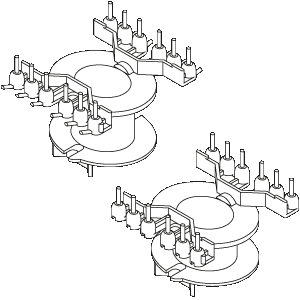

RM Power Conversion 45°, Specials

The coilformers are made in gfr Polyamide PA66 of type p6g (RTI long-range temperature +125°C). Pin material: tin bronze, tinned. Maximum solder temperature 350°C, 2 sec.

Special materials - eg. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The pin layout on the lower flange of these specially designed coilformers allows simultaneous binding-on and winding of two wires (bi-filar).

Compared with standard RM-coilformers, 12-32 solder-pins are available. In addition, winding and soldering can be done fully automatic.

Ordering Example

Please kindly take all details which are necessary to execute your order correctly from the ordering example (pdf-file).

Additional Product Informations

For explanatory and more detailed information on this coilformer-series please kindly see the attached pdf-file.

- Information of RM-Series

- Survey of Solder-pins and Solder-tags

- RM / RM LP Ferrite Cores

- List of Thermoplastic Materials

- Description Irradiation Cross-Linking