SMD-Series

- EE-SMD Coilformers (fm)

- EE-SMD - Coilformers (fu)

- EE-SMD Coilformers (LP)

- EFD-SMD Coilformers (fu)

- ER-SMD Coilformers (fm)

- ER-SMD Coilformers (fu)

- EP/EPX-SMD Coilformers (fm)

- EP-SMD Coilformers (fu)

- RM-SMD Coilformers (fm)

- RM-SMD Coilformers (fu)

- PC-SMD Coilformers (fm)

- PC-SMD Coilformers (fu)

- TR-SMD Surface Mount Bases (fm)

- TR-SMD Surface Mount Bases (fu)

- GP-SMD Carriers (fm)

- H-RG SMD Potting Boxes (fw)

- H-RG SMD Potting Boxes (ft)

- H-RG SMD Potting Boxes (LP)

- VLA-SMD Potting Boxes

- P-GP Pick and Place Caps

- P-EE Pick and Place Caps

- SMD - Snap-on Caps

- Spring-Clips SB-SMD, Latching Clips FB-SMD

- Ordering Example

- Additional Product Informations

This catalogue of coilformers contains information on all our products of the SMD-Series (Surface Mounted Devices)

Miniature electronic components, surface mountable, are used in ever increasing numbers in many areas of electronics. The requirements are: smallest dimensions, high temperature rating and fast solderability.

We supply coilformers in high quality thermoplastics, exactly to meet your production requirements ans product specification.

Wherever high-temperature soldering processes are used in connection with SMD-series coilformers, we recommend irradiated cross-linked plastics. This ensures that the mechanical properties - in particular those of gfr-polyamides - are maintained and breakages are reduced. For this reason NORWE offers all plastics components of the SMD-series in irradiated cross-linked materials.

In the short term, the cross-linked materials can be exposed to very high temperatures. Apart from improved aspects in production there may be interesting cost advantages, and a discussion with us could be useful.

Should you need further assistance we look forward to hearing from you.

Our extensive range of modular tooling allows almost unlimited constructional changes to meet customers specification, often by simple changes of tool inserts.

In addition the modular tooling system allows extremely short tooling times and can be very cost effective.

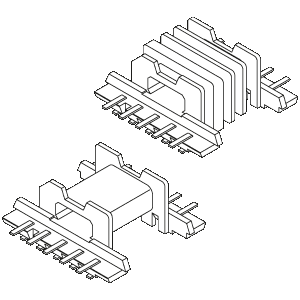

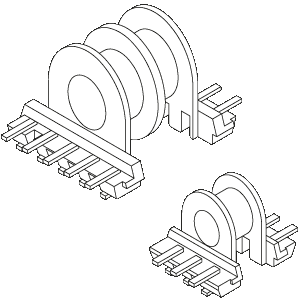

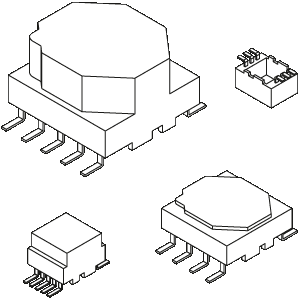

EE-SMD Coilformers (fm)

The coilformers are made in gfr Polyphenylene Sulfide PPS of type torA 504 (RTI long-range temperature +130°C) and are suitable for reflow soldering. Pin material: tin bronze, tinned.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coilformers have "gull-wing" terminals. To prevent melt-out, these should ideally be mechanically fixed when soldering on the wires. The coilformers are avialable with single or double sections. Automatic placing of the coilformers is possible by using a Pick and Place Cap.

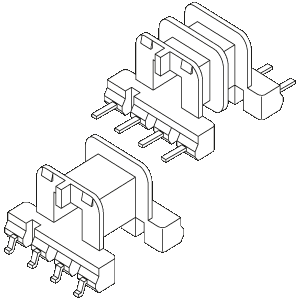

EE-SMD - Coilformers (fu)

The coilformers are made in gfr Polyphenylene Sulfide PPS of type torA 504 (RTI long-range temperature +130°C) and are suitable for reflow soldering. Pin Material: tin bronze, tinned.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coilformers have U-shaped terminals. This allows automatic binding-on of the wires, and after soldering leaves the pcb-side of the terminal clean and free from tin. The coilformers are available with single or double section.

Automatic placing of the coilformers is possible by using a Pick and Place Cap.

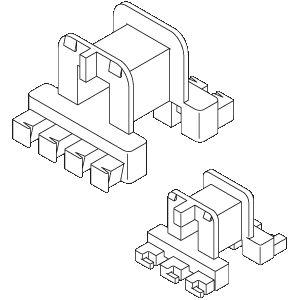

EE-SMD Coilformers (LP)

The coilformers are made in gfr Polyphenylene Sulfide PPS of type torA 504 (RTI long-range temperature +130°C) and are suitable for reflow soldering.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coilformers have no metal terminals. Wires are connected to plastic feet, which have a v-shaped slot for wrapping. The binding-on points of the wires provide the eventual connection to the pcb. These soldering points should be brushed blank before positioning onto the pcb.

Automatic placing of the coilformers is possible by using a Pick and Place Cap.

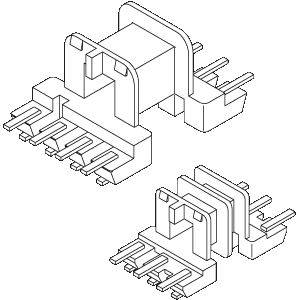

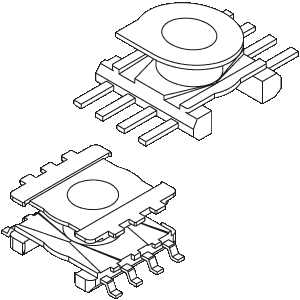

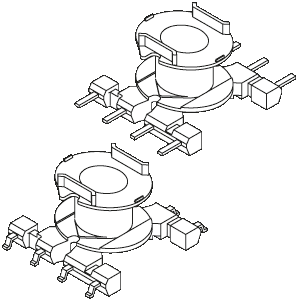

EFD-SMD Coilformers (fu)

The coilformers are made in gfr Polyphenylene Sulfide PPS of type torA 504 (RTI long-range temperature +130°C) and are suitable for reflow soldering. Pin material: tin bronze, tinned.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coilformers are fitted with U-shaped terminals. The two sides of the terminal allow automatic binding-on and soldering of the wires, leaving the pcb-side of the terminal free from tin.

Automatic placing of the coilformer and the ferrites is possible by using a Snap-on Cap. This cap is springloaded and keeps the ferrites and coilformer together. The coilformers are avialable with single, double and four sections.

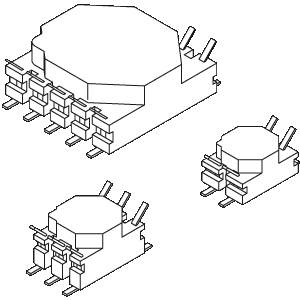

ER-SMD Coilformers (fm)

The coilformers are made in gfr Polyphenylene Sulfide PPS of type torA 504 (RTI long-range temperature +130°C) and are suitable for reflow soldering. Pin material: tin bronze, tinned.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coilformers are fitted with "gull-wing" terminals. To prevent melt-out, these should ideally be mechanically secured when soldering on the wires. Instead of glueing the ferrites, use can be made of the SB-ER Spring-Clips.

In addition a new version for automatic winding has been improved once again.

ER-SMD Coilformers (fu)

The coilformers are made in gfr Polyamide PA46 of type TE 250 F6 (RTI long-range temperature for V-0 (0.35) +65°C and for V-0 (0.75) +140°C) and are suitable for reflow soldering. Pin material: tin bronze, tinned.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coilformers are fitted with U-shaped terminals. The two sides of the terminal allow automatic binding-on and soldering of the wires, leaving the pcb-side of the terminal free from tin. Instead of glueing the ferrites, use can be made of the SB-ER Spring-Clips.

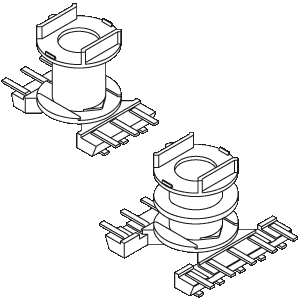

EP/EPX-SMD Coilformers (fm)

The coilformers are made in gfr Polyphenylene Sulfide PPS of type torA 504 (RTI long-range temperature +130°C) and are suitable for reflow soldering. Pin material: tin bronze, tinned.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coilformers are fitted with "gull-wing" terminals. To prevent melt-out, these should ideally be mechanically secured when soldering on the wires. Instead of glueing the ferrites, use can be made of the SB-EP Spring-Clips. Automatic placing of the coilformers and the ferrites is possible by using a Snap-on Cap. This cap is spring-loaded and keeps the ferrites and coilformer together.

EP-SMD Coilformers (fu)

The coilformers are made in gfr Polyphenylene Sulfide PPS of type torA 504 (RTI long-range temperature +130°C) and are suitable for reflow soldering. Pin material: tin bronze, tinned.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coilformers are fitted with U-shaped terminals. The two sides of the terminals allow automatic binding-on and soldering of the wires, leaving the pcb-side of the terminal free from tin.

Instead of glueing the ferrites, use can be made of the SB-EP Spring- Clips. Automatic placing of the coilformer and the ferrites is possible by using a Snap-on Cap. This cap is springloaded and keeps the ferrites and coilformer together. Slots in the Snap-on Caps allow additional glueing.

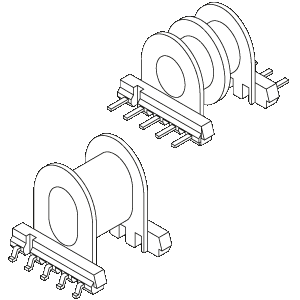

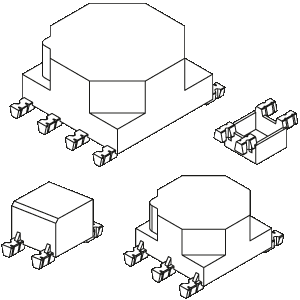

RM-SMD Coilformers (fm)

The coilformers are made in gfr Polyphenylene Sulfide PPS of type torA 504 (RTI long-range temperature +130°C) and are suitable for reflow soldering. Pin material: tin bronze, tinned.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The slot-design from the terminals into the winding section is suitable to accommodate wire guidance without change of the guide-axis. The tolerance compensator TA on the top flange eliminates the otherwise required insulation-washer. To prevent melt-out, the terminals should ideally be mechanically fixed when soldering.

RM-SMD Coilformers (fu)

The coilformers are made in gfr Polyphenylene Sulfide PPS of type torA504 (RTI long-range temperature +130°C) and made in gfr Polyamide PA66 of type A3X2G10 (RTI long-range temperature +115°C) and are suitable for reflow soldering. Pin material: tin bronze, tinned.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coilformers are fitted with U-shaped terminals. The two sides of the terminals allow automatic binding-on and soldering of the wires, leaving the pcb-side of the terminal free from tin.

The tolerance compensator TA on the top flange eliminates the otherwise required insulation washer.

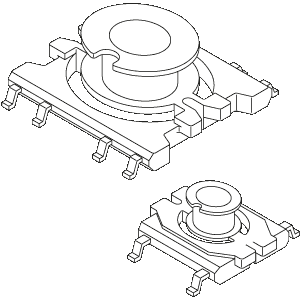

PC-SMD Coilformers (fm)

The coilformers are made in gfr Polyphenylene Sulfide PPS of type torA 504 (RTI long-range temperature +130°C) and are suitable for reflow soldering. Pin material: tin bronze, tinned.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coilformers have "gull-wing" terminals. To prevent melt-out, these should ideally be mechanically fixed when soldering on the wires.

PC-SMD Coilformers (fu)

The coilformers are made in gfr Polyphenylene Sulfide PPS of type torA 504 (RTI long-range temperature +130°C) and are suitable for reflow soldering. Pin material: tin bronze, tinned.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coilformers are fittet with U-shaped terminals. This allows automatic binding-on of the wires, and after soldering leaves the pcb-side of the terminal clean and free from tin.

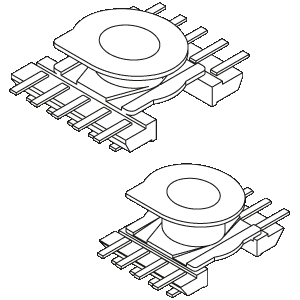

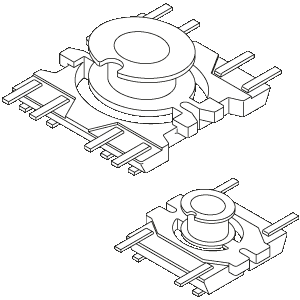

TR-SMD Surface Mount Bases (fm)

The surface-mount bases (fm) are made in gfr Polyphenylene Sulfide PPS of type torA504 (RTI long-range temperature +130°C) and are suitable for reflow soldering. Pin material: tin bronze, tinned.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The bases are fitted with 6 to 10 "gull-wing" type terminals, and are suitable to carry glued-on small toroidal windings or other small electronic components. This then allows automatic assembly of pcbs when fitted with Pick and Place Caps.

TR-SMD Surface Mount Bases (fu)

The surface-mount bases (fu) are made in gfr Polyphenylene Sulfide PPS of type torA504 (RTI long-range temperature +130°C) and are suitable for reflow soldering. Pin material: tin bronze, tinned.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The bases are fitted with 6 to 10 U-shaped terminals. The two sides of the terminal allow automatic binding-on and soldering of the wires, leaving the pcb-side of the terminal free from tin.

Surface mount bases are suitable to carry glued-on small toroidal windings or other small electronic components. This then allows automatic assembly of pcbs when fitted with Pick and Place Caps.

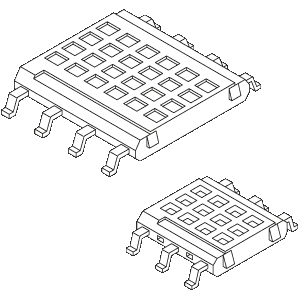

GP-SMD Carriers (fm)

The carrieres (fm) are made in gfr Polyphenylene Sulfide PPS of type torA504 (RTI long-range temperature +130°C) and are suitable for reflow soldering. Pin material: tin bronze, tinned.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

They are available in four diffrent sizes. "Gull-wing" type SMD terminals are fitted at the corners. To prevent melt-out, these should ideally be mechanically fixed when soldering on the wires. To facilitate automatic board assembly, Pick and Place Caps are available for the whole range.

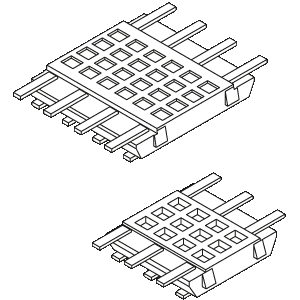

H-RG SMD Potting Boxes (fw)

The potting boxes (fw) are made in gfr Polyphenylene Sulfide PPS of type torA504 (RTI long-range temperature +130°C) and are suitable for reflow soldering. Pin material: tin bronze, tinned.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The potting boxes are for surface mounting, as is common f.e. with filter chokes and ISDN transformers. The terminal type fw ensures a defined distance between potting box and pcb. The binding-on / soldering section of the terminal is accessible from the outsite, the feet are easily positioned and electrical tests are possible.

H-RG SMD Potting Boxes (ft)

The potting boxes (ft) are made in gfr Polyphenylene Sulfide PPS of type torA504 (RTI long-range temperature +130°C) and are suitable for reflow soldering. Pin material: tin bronze, tinned.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The potting boxes are for surface mounting, and are suitable for house filter chokes or ISDN transformers. The binding-on / soldering section of the terminal ft is at the top end which leaves the SMD side of the terminal free from tin. The boxes are suitable for low profile applications.

H-RG SMD Potting Boxes (LP)

The potting boxes (LP) are made in gfr Polyphenylene Sulfide PPS of type torA504 (RTI long-range temperature +130°C) and are suitable for reflow soldering.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The potting boxes have no metal terminals. Wires are connected to plastic feet, which have a V-shaped slot for wrapping. The binding-on points of the wires provide the eventual connection to the pcb. These soldering points should be brushed blank before positioning onto the pcb.

VLA-SMD Potting Boxes

The boxes are made in gfr Polyphenylene Sulfide PPS of type torA504 (RTI long-range temperature +130°C) and are suitable for reflow soldering conditions.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The boxes are suitable for the EE-SMD-coilformers with "gullwing" terminals (fm) and EE-SMD-coilformers with plastic feet design (LP). Exact positioning on the board is achieved by utilizing placement ribs on the outside of the boxes.

When ordering please quote type and order-code.

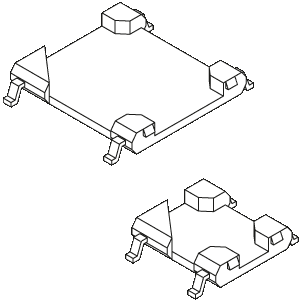

P-GP Pick and Place Caps

The Pick and Place Caps are made in gfr Polyphenylene Sulfide PPS of type torA504 (RTI long-range temperature +130°C) and are suitable for reflow soldering conditions.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The Pick and Place Caps allow automatic assembly of boards for components mounted on SMD-Carriers (GP) or SMD-Surface Mount Bases (TR-SMD). They connect with the SMD-Carriers and SMD-Base via a snap-on facility.

When ordering please quote type and order-code.

P-EE Pick and Place Caps

The Pick and Place Caps are made in gfr Polyphenylene Sulfide PPS of type torA504 (RTI long-range temperature +130°C) and are suitable for reflow soldering conditions.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The Pick and Place Caps for the range EE 5 - EE 20 allow automatic board assembly. They are designed to fit the top of the flanges of the SMD coilformers via a snap-on facility.

When ordering please quote type and order-code.

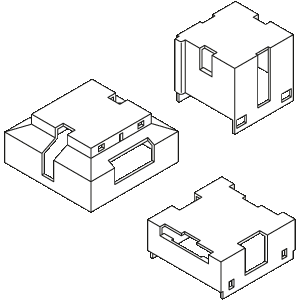

SMD - Snap-on Caps

The Snap-on Caps are made in gfr Polyamide PA66 of type eg7 (RTI long-range temperature +120°C).

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The spring-action Snap-on Cap allows quick assembly of the coilformers and the cores in their correct positioning. The caps have openings at the sides which allows additional glueing. They have a smooth top and can be used for pick-and place.

When ordering please quote type and order-code.

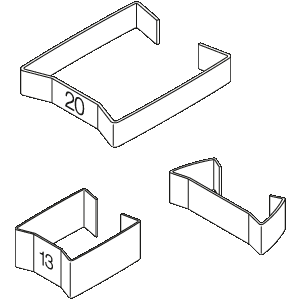

Spring-Clips SB-SMD, Latching Clips FB-SMD

The Spring-Clips are for assembling the ferrite cores and holding them together. The process is simple and cost-effective. The clips surround the whole outside of the ferrite cores and keep them under constant pressure. Variations of operating temperature has no effect on clamping pressure. One clip is required per assembly.

Latching Clips are made in stainless steel and have been designed for the automatic and cost effectiver assembling of ferrite cores to the coilformer. Upon request and depending on the type of coilformers suitable assembly jigs can be made available. Two clips are required per assembly.

Special materials and designs on request, dimensions in mm/inch.

Ordering Example

Please kindly take all details which are necessary to execute your order correctly from the ordering example (pdf-file).

Additional Product Informations

For explanatory and more detailed information on this coilformer-series please kindly see the attached pdf-file.

- Information of SMD - Surface Mount Devices

- EE, EFD, ER, EP, EPX, RM, P(PC) Ferrite Cores

- List of Thermoplastic Materials

- Description Irradiation Cross-Linking