3D printing technology provides various processes, depending on the area of application. The basis of all processes is a 3D CAD design to generate the geometric data for the printer.

Additive component production is very varied. To allow better differentiation, the production processes are splitted into 3 main groups:

- Rapid Prototyping

- Production of prototypes for product development

- Rapid Tooling

- Production of tool components, e.g. for injection moulding tools

- Rapid Manufacturing

- Production of series parts

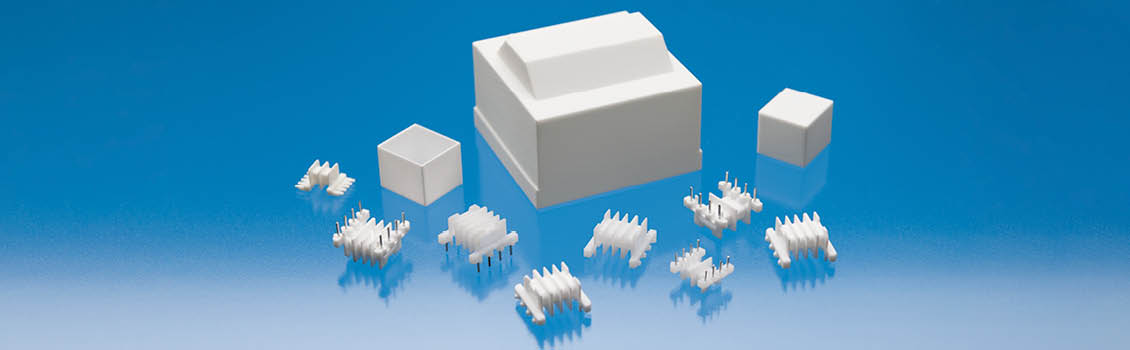

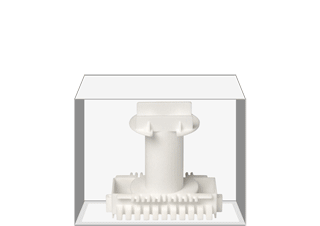

Selective laser sintering (SLS) is the production process currently used by NORWE, as this technology is ideal for prototypes and small series (rapid manufacturing). The powdered material is applied in layers and melted or sintered using a laser.

Selective laser sintering at NORWE

There are several advantages to using SLS for producing components for coilformers and boxes. The design is very accurate in every detail and various materials and colours are available. The SLS process produces components, which can be used directly without additional expenditure during printing, such as support structures. Care must however be taken to ensure that the designs are optimized for easy printing with a 3D printer in order to compensate height tolerances, for example.

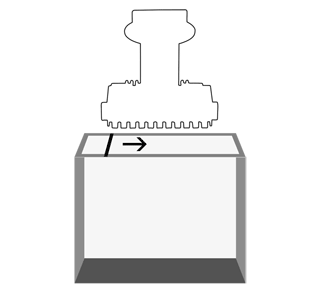

Step 1

Application of a thin powder layer, e.g. of polyamide 12 plastic.

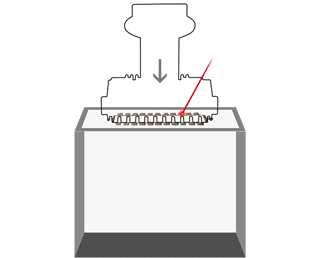

Step 2

Melting the powder across the component cross section using a laser.

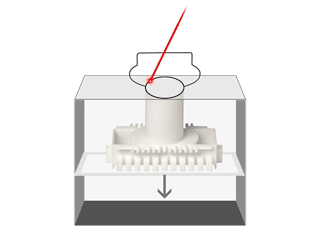

Step 3

The component descends step by step. During descent, additional layers of powder are applied until the component is complete.

In addition to the SLS process, the FDR ( Fine Detail Resolution) process is ideal for small, detailed components.

The new technology impresses with very filigree structures with extremly fine surfaces - the FDR process in 3D printing achieves a previously unfeasible level of precision. Highly stable components with the smallest measurements and extremly-thin wall thickness are the highlight of this most recent technology - which is possible due to a finebeam laser and the use of an extremly tough yet flexible material. These possible, high-precision components open up new areas of operation as a part of series production, especially through their use in electronic components.