ETD/EER-Series

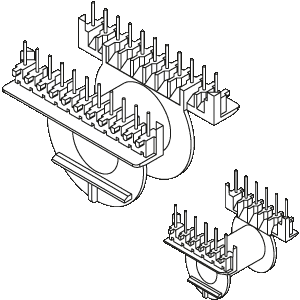

- ETD Coilformers Horizontal

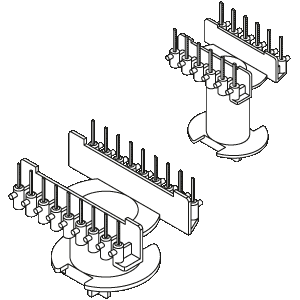

- ETD Coilformers Vertical

- ETD Safety Class Coilformer Concentric Design

- EER Coilformers Horizontal

- EER Coilformers Vertical

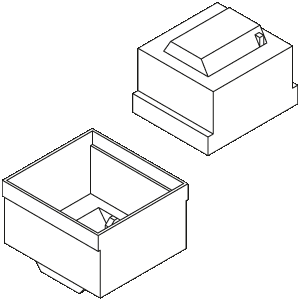

- ETD Potting Boxes Horizontal

- ETD lr Potting Boxes Horizontal

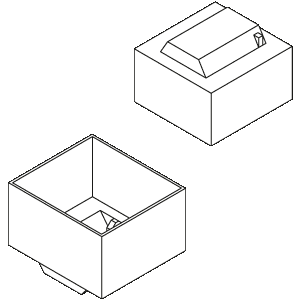

- ETD Potting Boxes Vertical

- Safety Class with Spacers DR

- Clips FK-ETD

- Ordering Example

- Additional Product Informations

All our products of the ETD and EER-Series

Components of the ETD-Series and EER-Series are on-developments of the well known EC-range. They have been developed specially for converters in switch-mode power supplies. We supply components made in high quality thermoplastics, matching your production requirements.

Wherever high-temperature soldering processes are used, we recommend irradiation cross-linked thermoplastics. Cross-linked materials can be exposed to short, but very high peak temperatures. Beside improved production aspects there may be also interesting cost advantages.

Our extensive range of modular tooling allows constructional changes to customers specification by simple changing tool inserts. In addition the modular tooling system allows short tooling times and can be very cost effective.

Should you need further assistance we look forward to hearing from you.

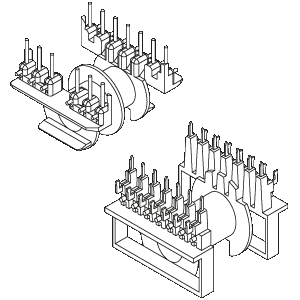

ETD Coilformers Horizontal

The coilformers are made in gfr Polyethylene Terephthalate PET of type SKYT.5220FR (RTI long-range temperature +155°C). Pin material is tin bronze, tinned for solder-pins and brass, tinned for solder-tags. Max. solder temperature 350°C, 2 sec.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coilformers are avialable in the latest design ETD lr and in the well-established versions ETD standard with solder-pins and ETD standard with solder-tags.

For each application the most suitable solution - inform yourself about the individual qualtities of the different designs on product informations.

ETD Coilformers Vertical

The coilformers are made in gfr Polyethylene Terephthalate PET of type SKYT.5220FR (RTI long-range temperature +155°C). Pin material is tin bronze, tinned for solder-pins and brass, tinned for solder-tags. Max. solder temperature 350°C, 2 sec.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coilformers are avialable in the well-established versions ETD standard with solder-pins and ETD standard with solder-tags. For each application the most suitable solution - inform yourself about the individual qualtities of the different designs on product informations.

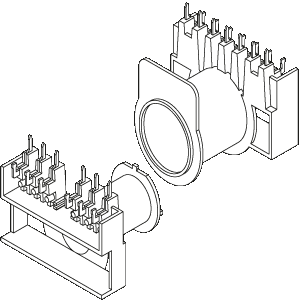

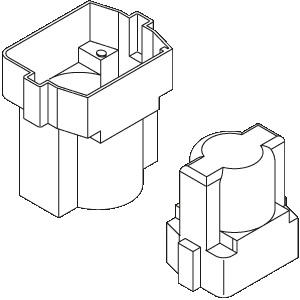

ETD Safety Class Coilformer Concentric Design

The coilformers are made in gfr Polyamide PA66 of type A RV250 nat. (RTI long-range temperature +100°C). The solder-tags are punched from brass and are subsequently tinned. Soldering temperature 350°C max. up to 2 sec.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The ETD safty class coilformers have the advantage that the primary and secondary windings are wound seperately on the coilformer halves, with the two windings pushed together to form a complete winding assembly.

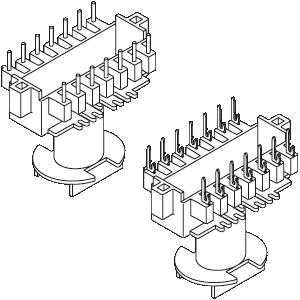

EER Coilformers Horizontal

The coilformers are made in gfr Polyethylene Terephthalate PET of type SKYT.5220FR (RTI long-range temperature +155°C). Pin material is tin bronze, tinned. Max. solder temperature 350°C, 2 sec.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coilformers are available in the latest design with solder-pins.

For each application the most suitable solution - inform yourself about the individual qualities of the different designs on product informations.

EER Coilformers Vertical

The coilformers are made in gfr Polyethylene Terephthalate PET of type SKYT.5220FR (RTI long-range temperature +155°C). Pin material is tin bronze, tinned. Max. solder temperature 350°C, 2 sec.

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The coilformers are available in the latest design with solder-pins.

For each application the most suitable solution - inform yourself about the individual qualities of the different designs on product informations.

ETD Potting Boxes Horizontal

The boxes are made in gfr Polyamide PA66 of type A RV250 nat. (RTI long-range temperature +100°C).

Special materials - e.g. irradiated cross-linked - and design on request, dimensions in mm/inch.

The boxes are suitable as enclosures for horizontal ETD standard coilformers.

When ordering please quote type and order-code.

ETD lr Potting Boxes Horizontal

The boxes are made in gfr Polyamide PA66 of type A RV250 nat. (RTI long-range temperature +100°C).

Special materials - e.g. irradiated cross-linked - and design on request, dimensions in mm/inch.

The potting boxes with a height reduced are specially suitable for the new design of coilformers ETD lr which feature a minimized weight and overall height.

When ordering please quote type and order-code.

ETD Potting Boxes Vertical

The boxes are made in gfr Polyamide PA66 of type A RV250 nat. (RTI long-range temperature +100°C).

Special materials - e.g. irradiated cross-linked - and design on request, dimensions in mm/inch.

The boxes are suitable as enclosures for vertical ETD coilformers. (Not suitable für ETD coilformers with side-wrapping pins.)

When ordering please quote type and order-code.

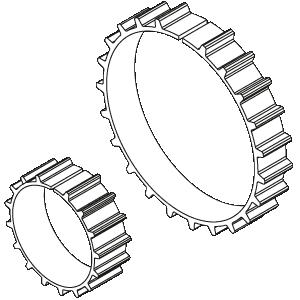

Safety Class with Spacers DR

Spacers are made in gfr Polyamide PA66 of type A RV250 nat. (RTI long-range temperature +100°C), or gfr Polyethylene Terephthalate PET of type SKYT.5220FR (RTI long-range temperature +155°C).

Special materials - e.g. irradiated cross-linked - and designs on request, dimensions in mm/inch.

The application of spacers DR in round winding section is advantageous for achieving required creepage and clearances between primary and secondary, and to the core. The spacers can be used cumulative for all dimensions.

When ordering please quote type and order-code.

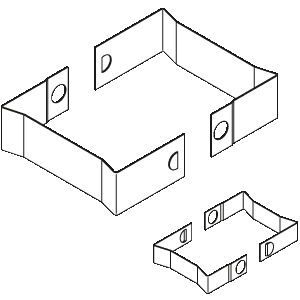

Clips FK-ETD

Suitable types of glues, such as Araldite, can be used to put ETD cores together. Constant pressure must be maintained on the core-halfes until the glue has hardened. More advantageous and economic are the easily assembled clips FK. They are in stainless steel and can be used for both horizontal and vertical assemblies.

The clamping pressure on the core-halves remains practically constand regardless of temperature, and no pull is exerted on the coilformer. Two clips are required per coilformer. A drop of glue may be used to connect coilformer and ferrite, also preventing frequency-noise. Other material thicknesses on request.

When ordering please quote type and order-code.

Ordering Example

Please kindly take all details which are necessary to execute your order correctly from the ordering example (pdf-file).

Additional Product Informations

For explanatory and more detailed information on this coilformer-series please kindly see the attached pdf-file.

- Information of ETD/EER-Series

- Description Spacer DR

- Survey of Solder-pins

- Servey of Solder-tags

- List of Thermoplastic Materials

- Description Irradiation Cross-Linking

- ETD Ferrite Cores

- EER Ferrite Cores